-

Acoustics

Acoustics

Acoustics engineers perform research on problems of both a basic and applied nature in physical...

Learn more

-

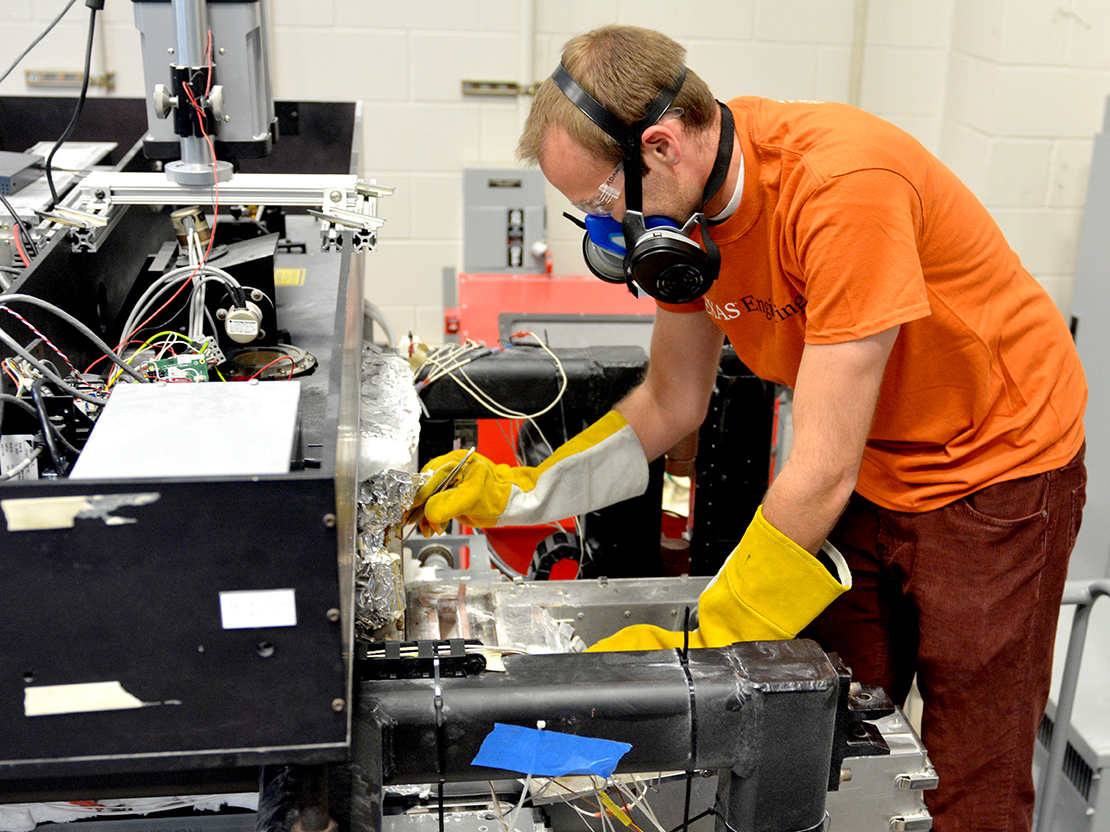

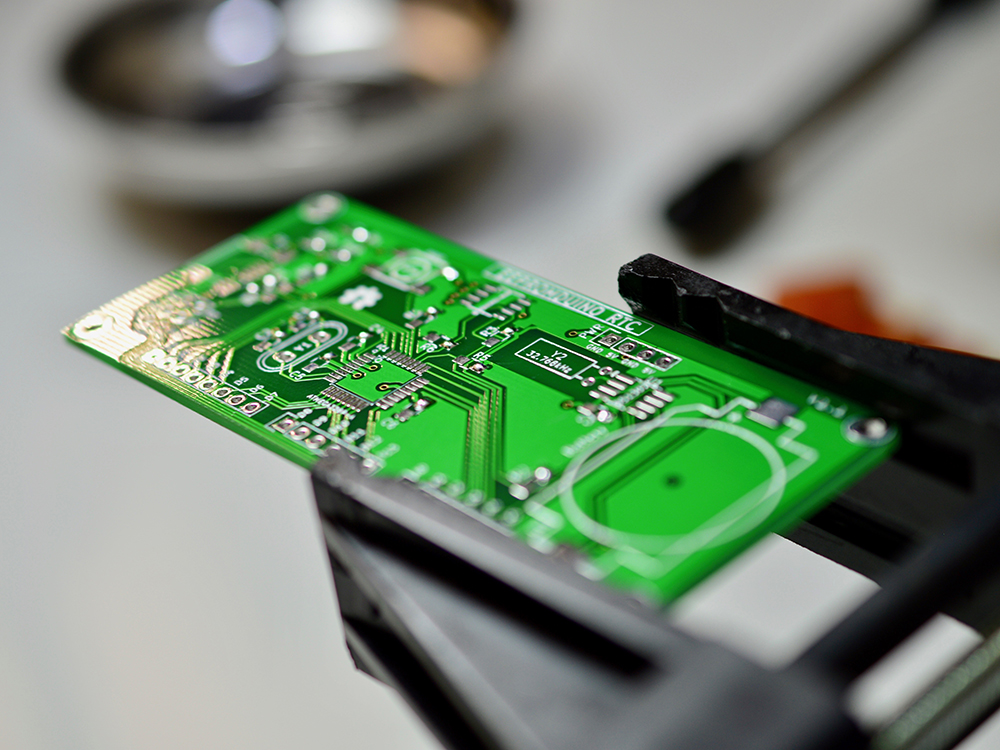

Advanced Manufacturing and Design

Advanced Manufacturing and Design

Advanced Manufacturing and Design uses technological advances to create products and systems that...

Learn more

-

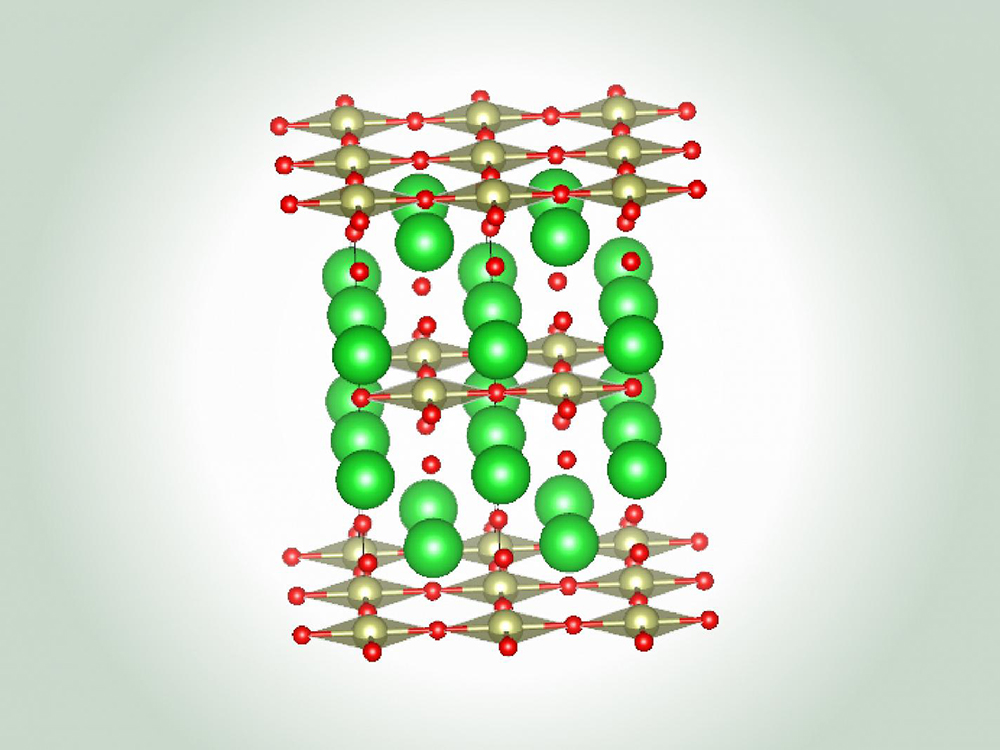

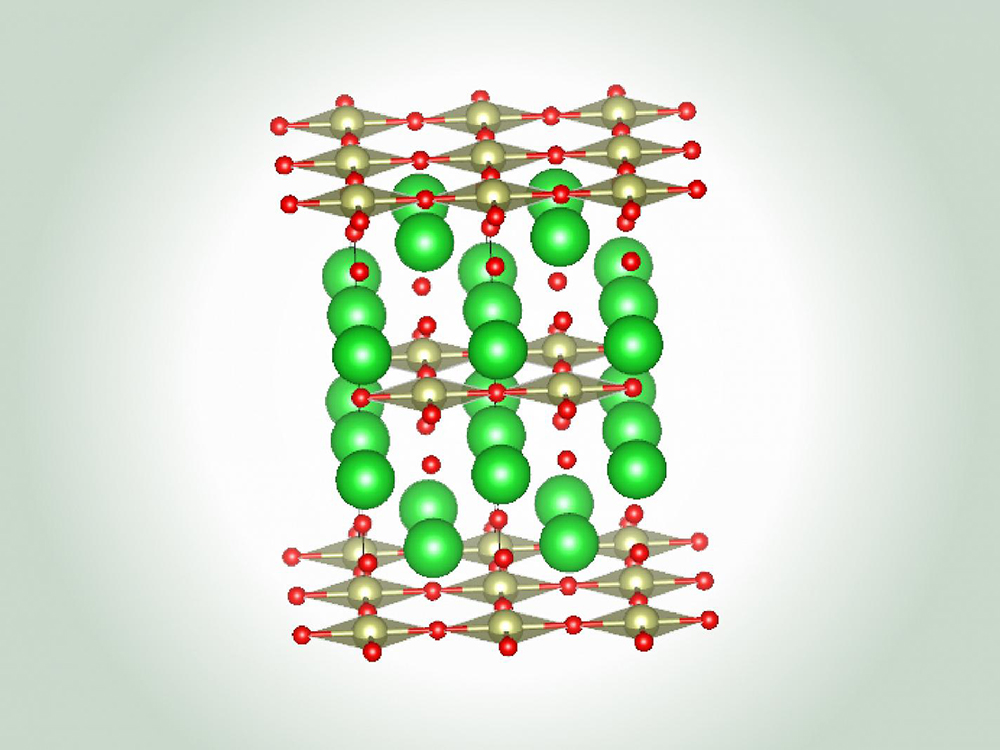

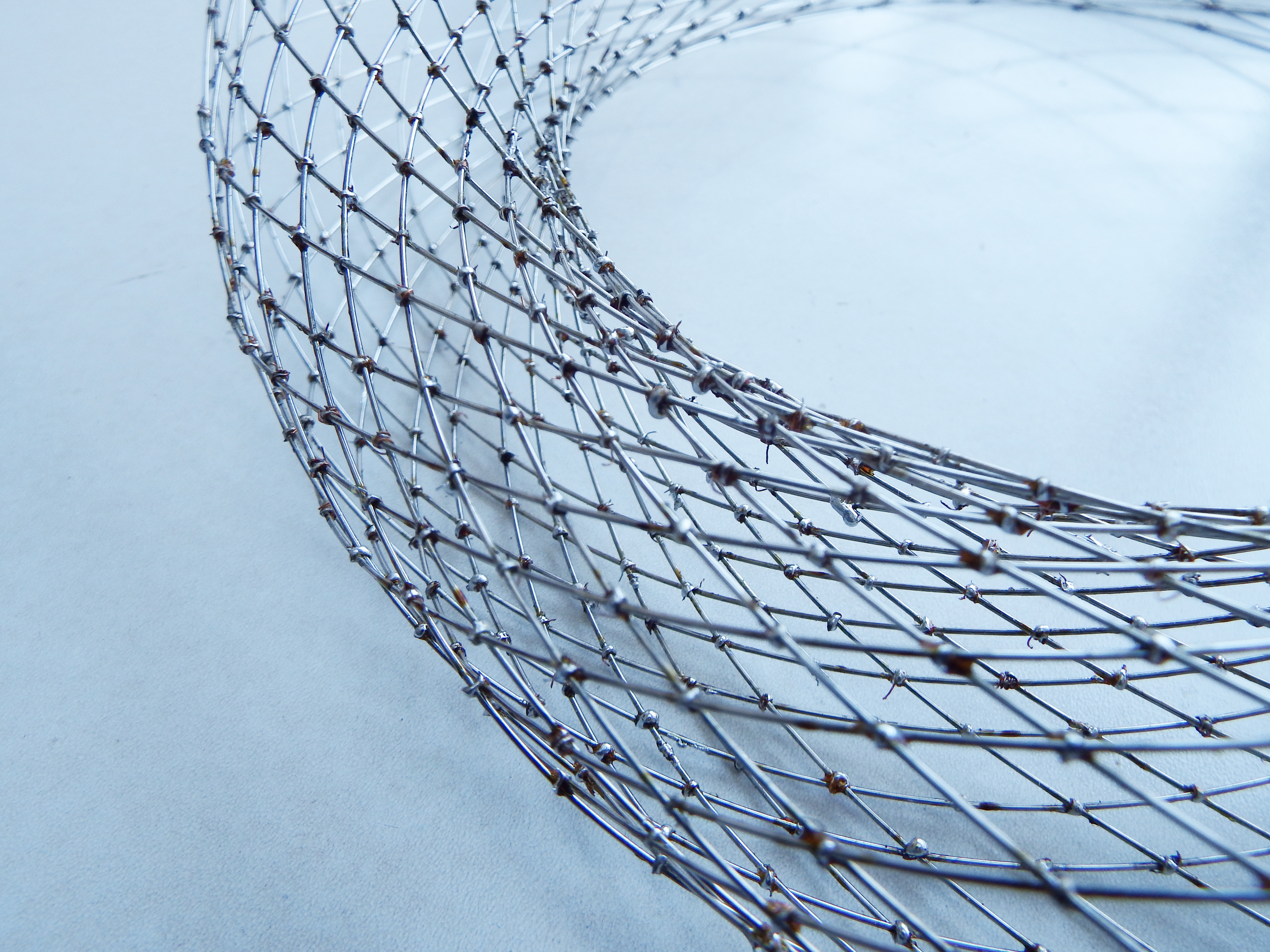

Advanced Materials Science and Engineering

Advanced Materials Science and Engineering

The Advanced Materials Science and Engineering research area in the Walker Department of...

Learn more

-

Analytics and Probabilistic Modeling

Analytics and Probabilistic Modeling

Decisions are often difficult because the outcome is uncertain. Researchers focused on Analytics...

Learn more

-

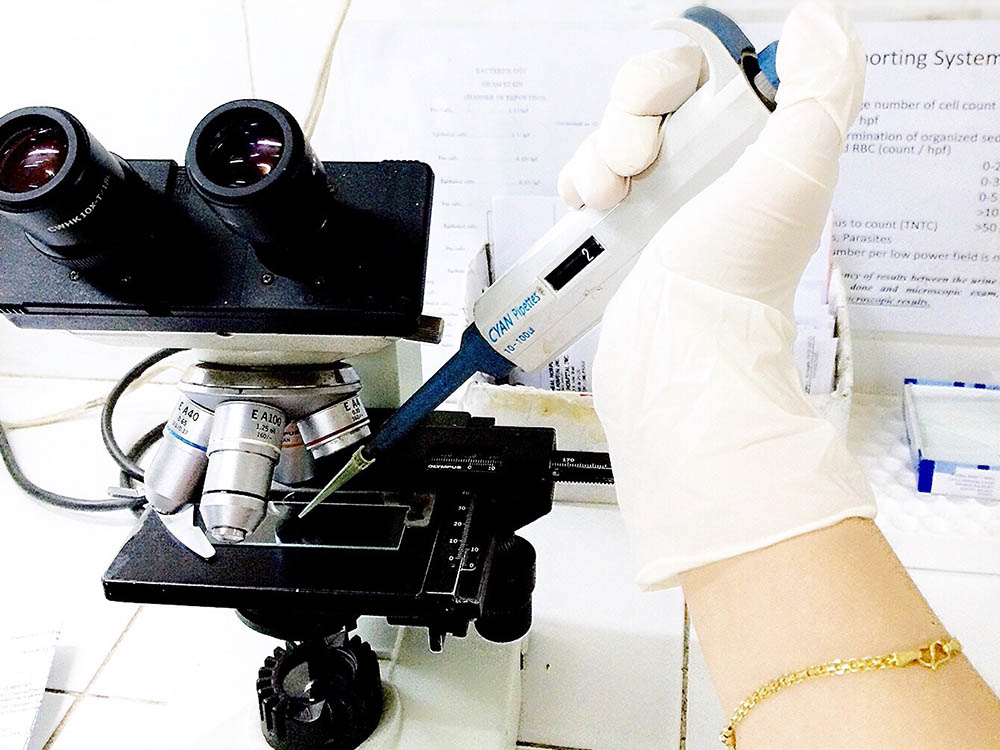

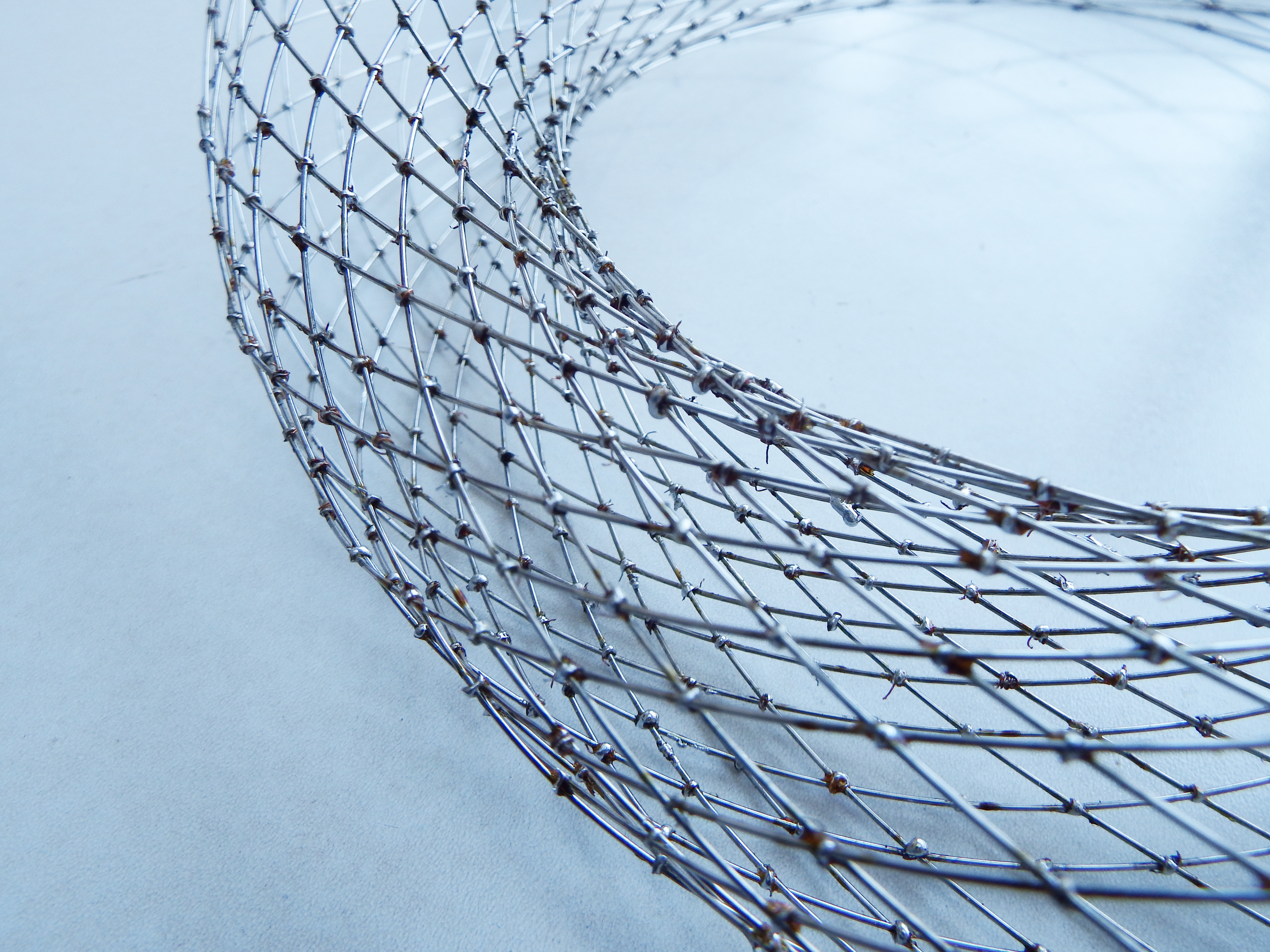

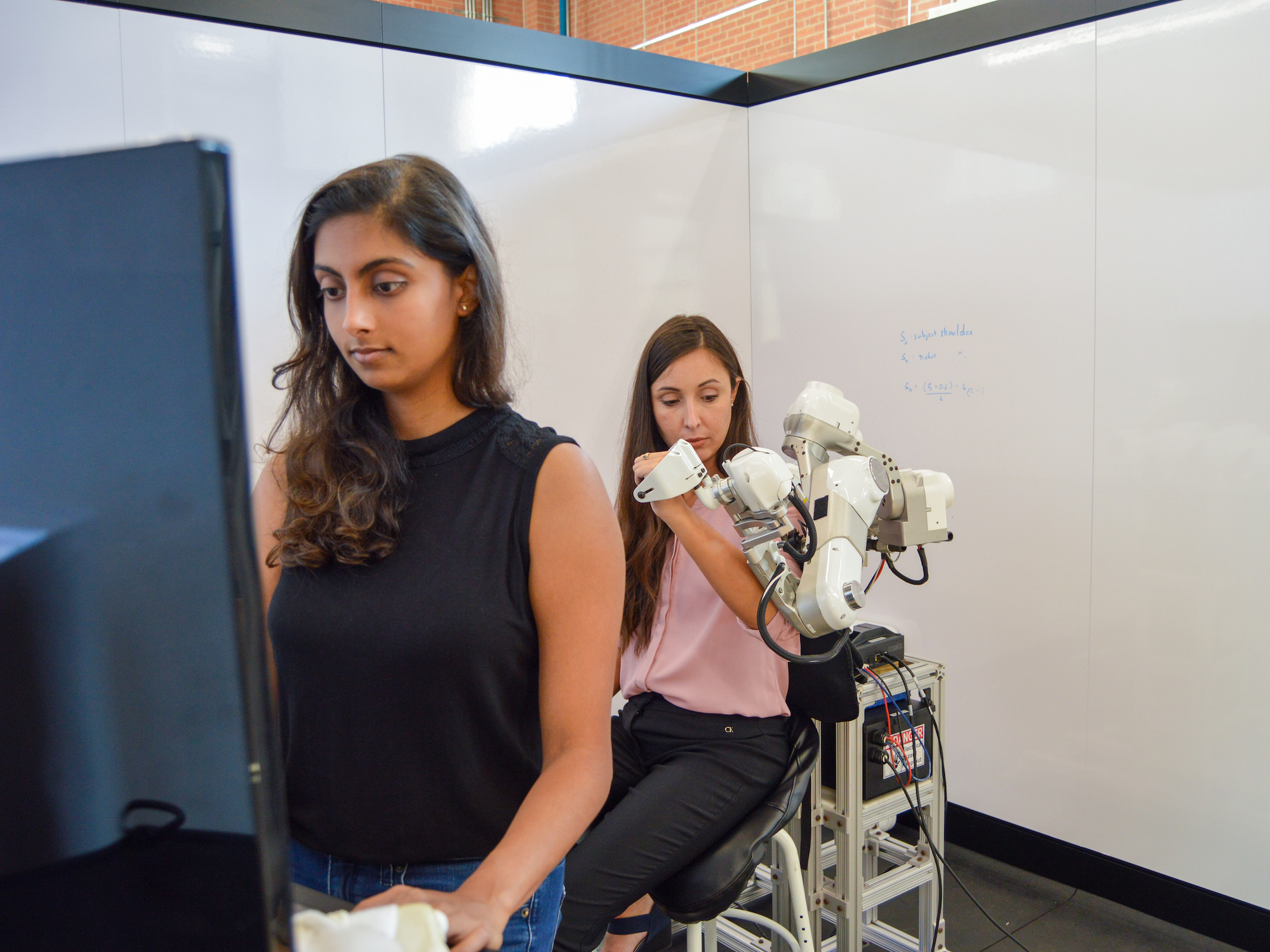

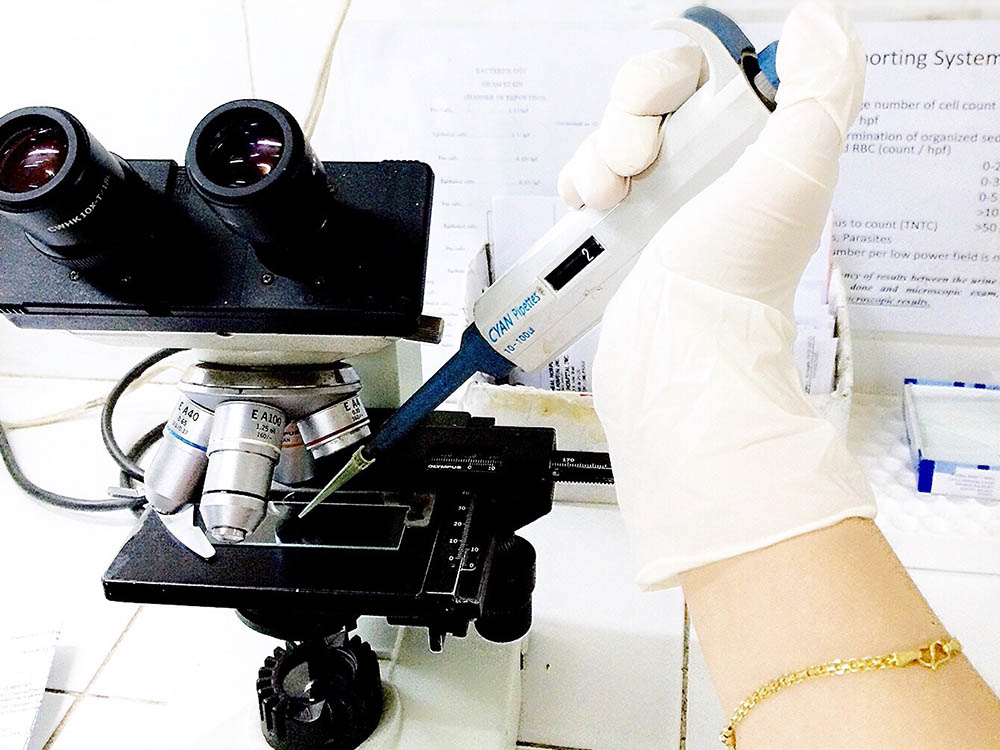

Biomechanical and Biomedicine

Biomechanical and Biomedicine

Biomechanics is the application of fundamental mechanical engineering principles to biological...

Learn more

-

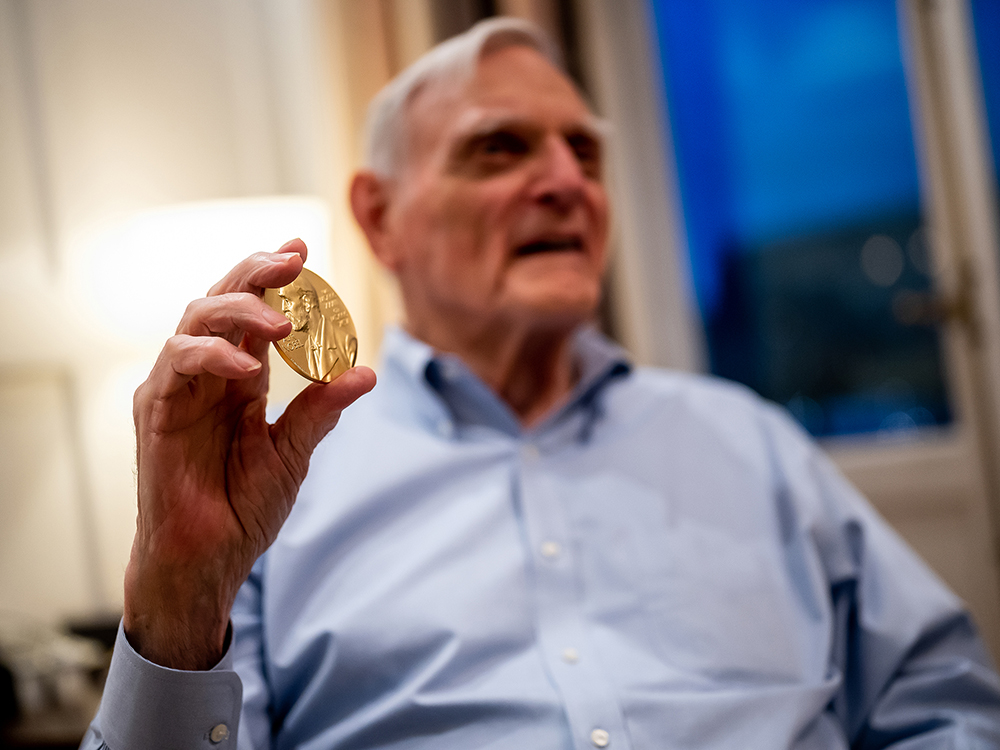

Clean Energy Technology

Clean Energy Technology

Clean energy technology research focuses on advancing clean energy technology at every stage, from...

Learn more

-

Complex Systems

Complex Systems

Complex Systems includes the science, mathematics and engineering of systems with simple...

Learn more

-

Computational Engineering

Computational Engineering

Computational engineers develop and apply the computational models, data assimilation techniques,...

Learn more

-

Engineering Education

Engineering Education

Engineering Education research focuses on understanding how best to recruit, retain and prepare a...

Learn more

-

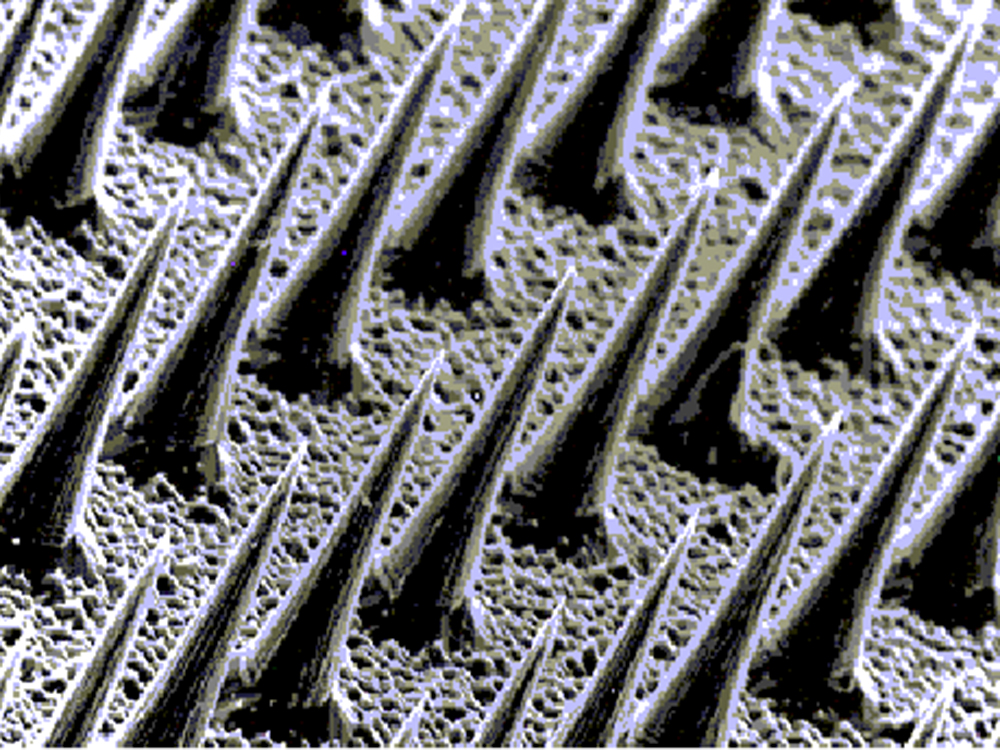

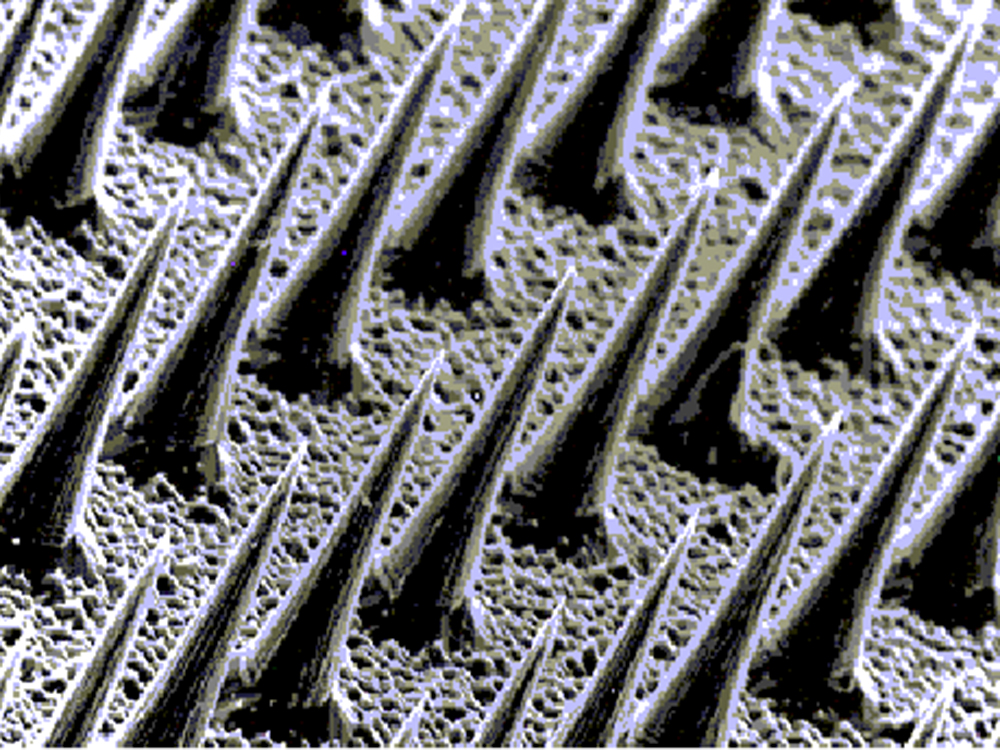

Nano and Micro-scale Engineering

Nano and Micro-scale Engineering

As materials, mechanisms, and machines are scaled down to the micro- and nano-scales, new physical...

Learn more

-

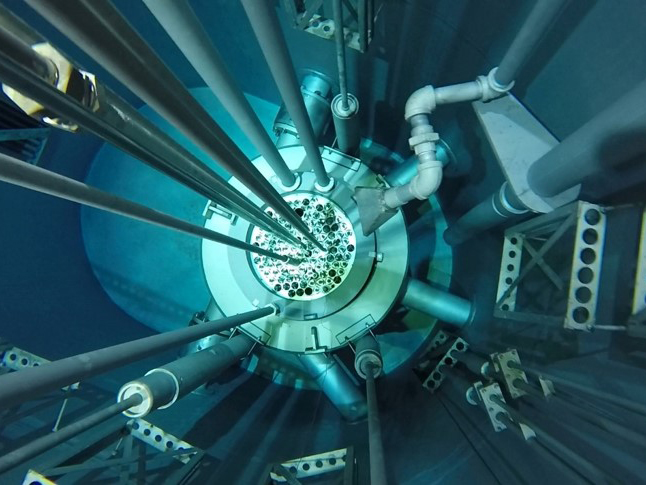

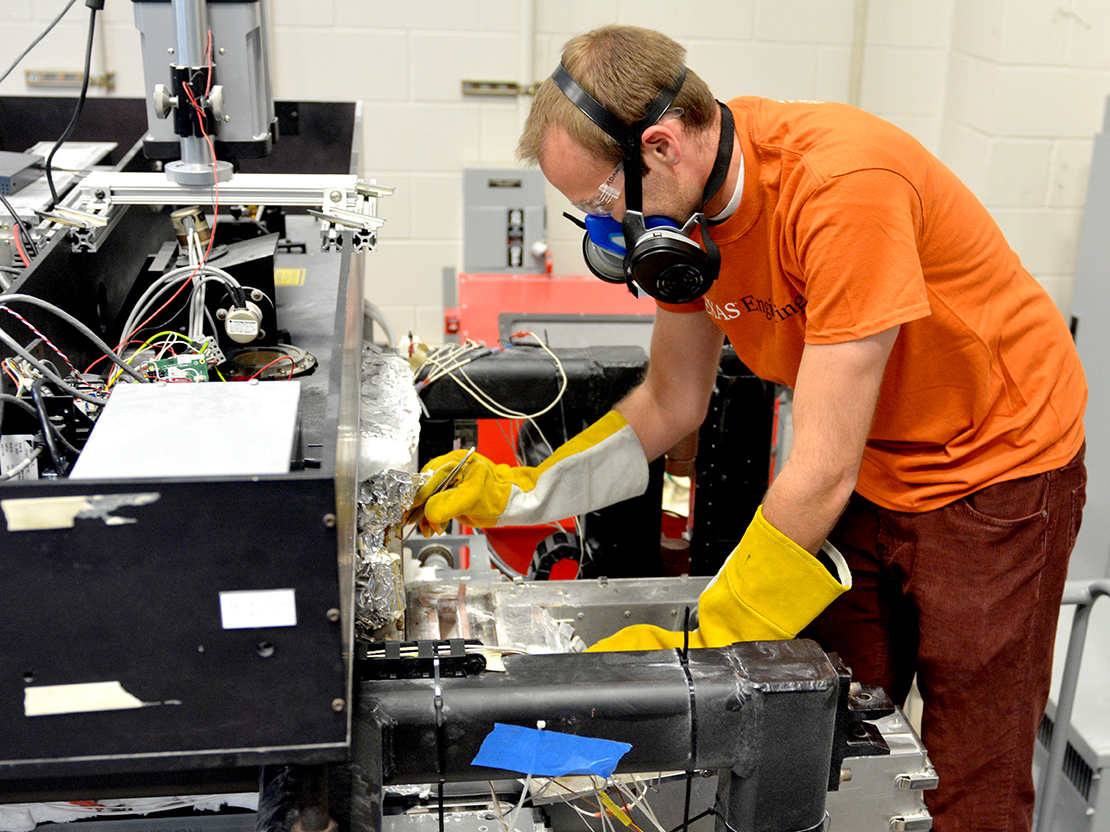

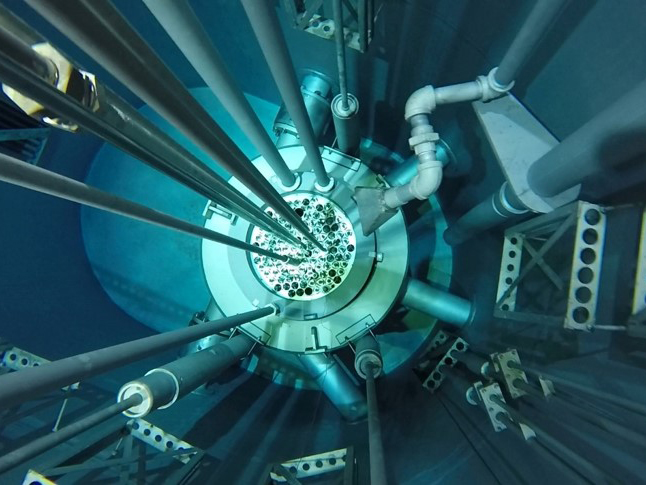

Nuclear and Radiation Engineering

Nuclear and Radiation Engineering

Encompasses health physics, radiation engineering, research reactor beam port experiments,...

Learn more

-

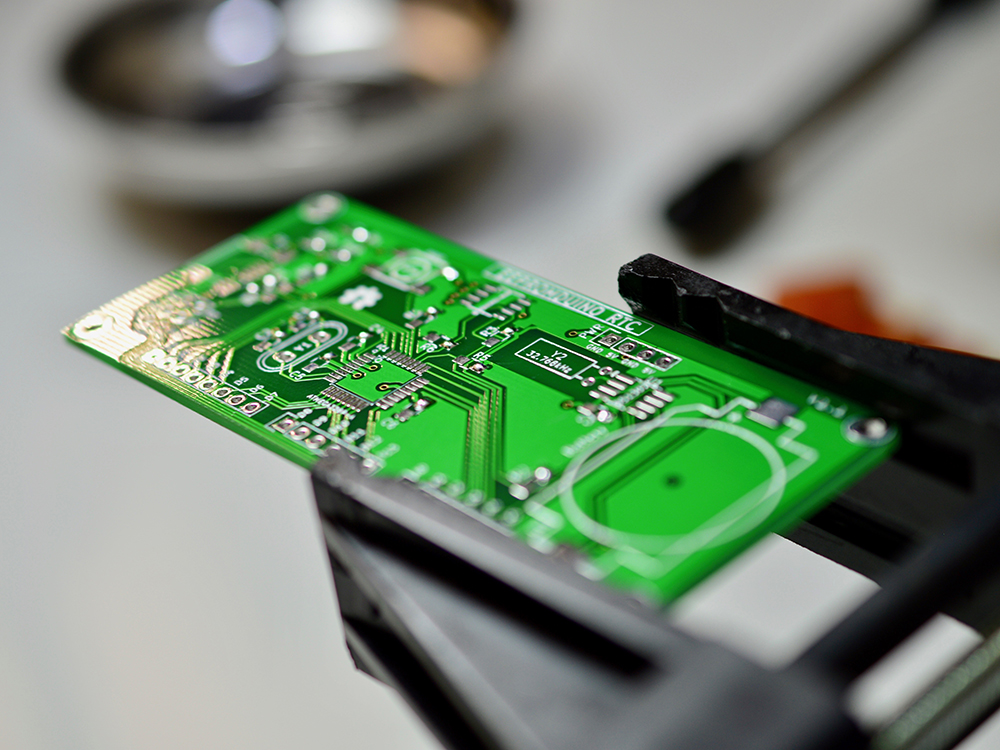

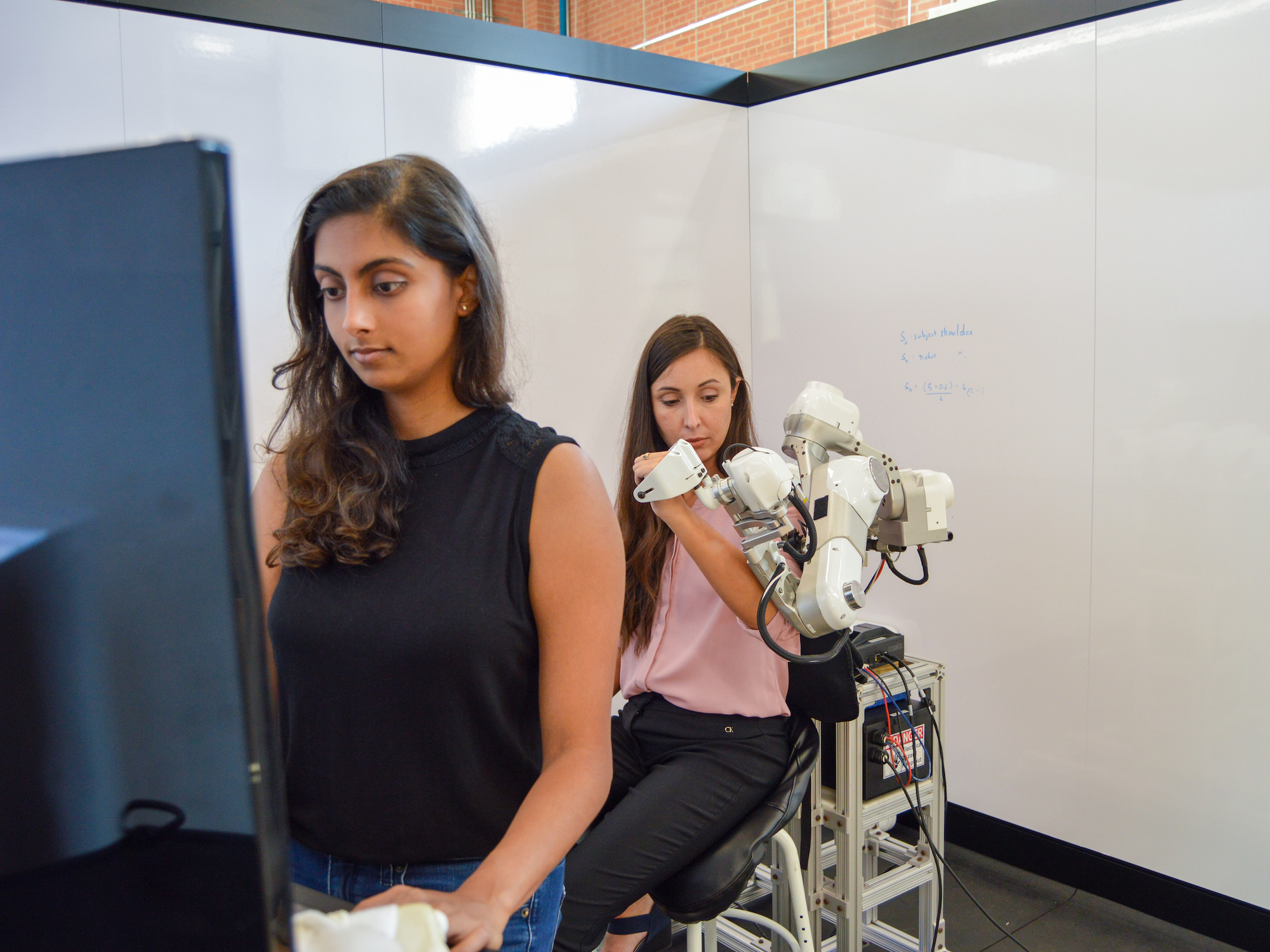

Robotics and Intelligent Mechanical Systems

Robotics and Intelligent Mechanical Systems

Robotics and intelligent machines are emerging as prime technologies that can provide a wide range of...

Learn more